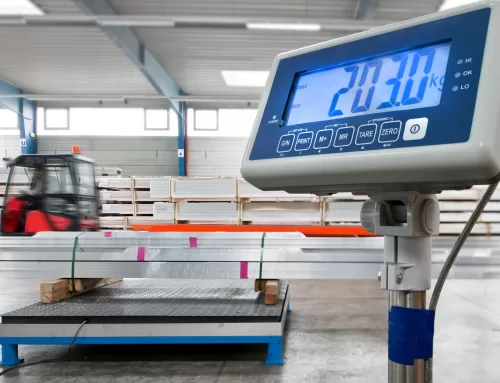

Calibration is an essential process that ensures the accuracy and reliability of weighing equipment.

For businesses that rely on precise measurements, understanding various scale calibration methods is crucial.

Active Scale specializes in providing expert calibration services that cater to diverse needs, whether for commercial or industrial applications.

This blog will delve into different methods of scale calibration, including their benefits and procedures.

Scale Calibration Methods: An Overview

Scale calibration is the process of adjusting the measurement accuracy of a scale.

The primary objective is to ensure that the scale provides readings that are consistent with known standards.

Active Scale employs several methods to achieve accurate scale calibration, ensuring that your weighing equipment remains compliant and reliable. Each method has its unique advantages and choosing the right one can significantly impact the accuracy of your measurements.

The Importance of Calibration Weights and Certified Weights

Calibration weights are essential tools used in the scale calibration process. These weights provide a known mass that can be used to test the accuracy of a scale.

Active Scale utilizes certified weights that are traceable to national standards, ensuring adherence to industry regulations. Given that weigh scales are precision measuring devices with much higher accuracy and resolution than other measuring devices, using certified weights is crucial for maintaining legal for trade calibration.

This precision is especially vital in environments exposed to vibration, impact loading, high humidity, and corrosive chemicals.

Comparative Calibration: A Reliable Approach

Comparative calibration is a method that involves comparing the readings of the scale being tested to those of a known standard scale.

This method is beneficial when direct calibration is not feasible. Active Scale uses comparative calibration to determine discrepancies and make necessary adjustments.

This method is especially useful in environments where high precision is required, as it ensures that the scale functions correctly in comparison to another accurate scale.

The Substitution Method and Electronic Calibration

The substitution method is another calibration approach that can be utilized when direct measurement is challenging. This method involves replacing the weight of the item being weighed with a known calibration weight to verify the scale’s accuracy.

Active Scale implements this method effectively to ensure accurate readings.

Electronic calibration is increasingly popular due to its efficiency and precision. This method uses electronic devices to calibrate scales automatically, reducing the potential for human error.

Active Scale offers electronic calibration services that streamline the calibration procedure and improve the overall accuracy of your weighing equipment.

Regular Recalibration: Ensuring Accuracy Over Time

Due to the nature of scales and the environments they operate in—such as extreme temperatures, exposure to rain, and high levels of vibration—regular recalibration is essential.

Active Scale recommends recalibration at least once a year, though, for high-cost commodities, monthly recalibration can be warranted.

Their trained professional technicians use traceable Measurement Canada Certified Mass Standards for calibration, covering everything from high precision Class II scales to Class III industrial scales and Class IIIHD high-capacity scales.

In summary, various methods of scale calibration are essential for maintaining the accuracy and reliability of weighing equipment.

From calibration weights and certified weights to comparative calibration and electronic calibration, Active Scale provides comprehensive services tailored to meet your needs. Ensuring calibration tolerance and compliance with legal standards is vital for any business.

If you need expert calibration services, reach out to Active Scale today.

Let us help you maintain the accuracy of your scales for optimal performance!

For personalized assistance, contact our Service Division for a consultation regarding your needs and estimates of cost at 1-866-284-2223.