TUFF/DECK

Load Cell Assembly

Superior Load Sensing Technology

The Unique Design of Tuff-Deck Load Cells

The standard Tuff-Deck steel vehicle scale utilizes a self-restoring rocker pin design load cell, 30-ton capacity each, with 150% safe working overload, and 350% ultimate overload capability.

This load cell is manufactured from 17-4 PH and 316 stainless steel materials and is highly resistant to corrosion. The latest manufacturing technologies are utilized in its construction, including laser welding. The load cells have factory matched outputs, requiring minimal field adjustments on initial and subsequent calibrations. The rocker pin is purged and filled with inert gas, hermetically sealed to IP68 (submersion at one metre for 100 hours) and IP69K (high-pressure steam jet) standards, is NTEP-approved Class III L 10,000 d, and OIML approved to R60 specifications.

The signal cable from the load cells has an internal braided shield to protect from R.F.I. There is a heavy-duty external braid to provide mechanical protection from abrasion damage and chewing rodents.

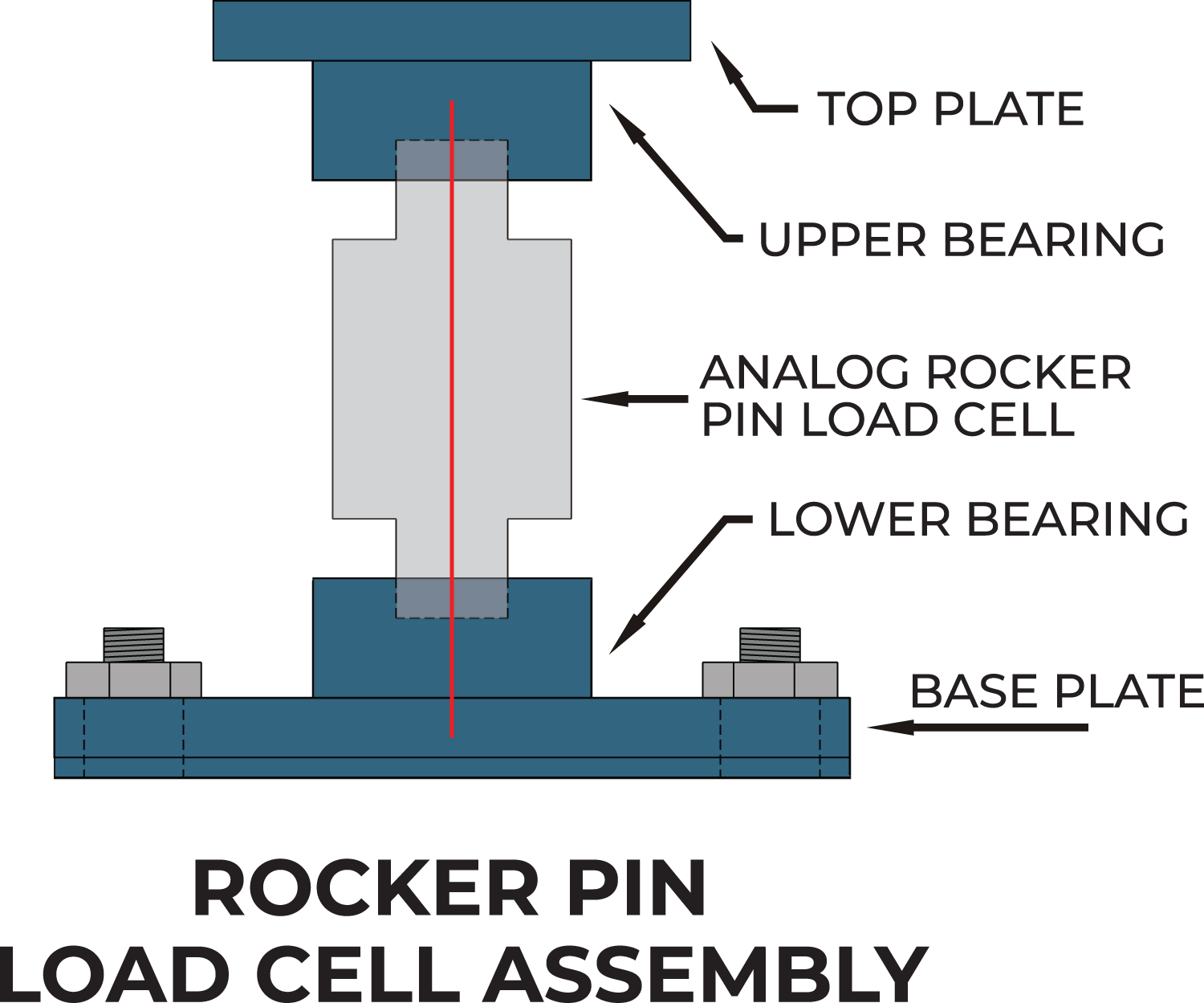

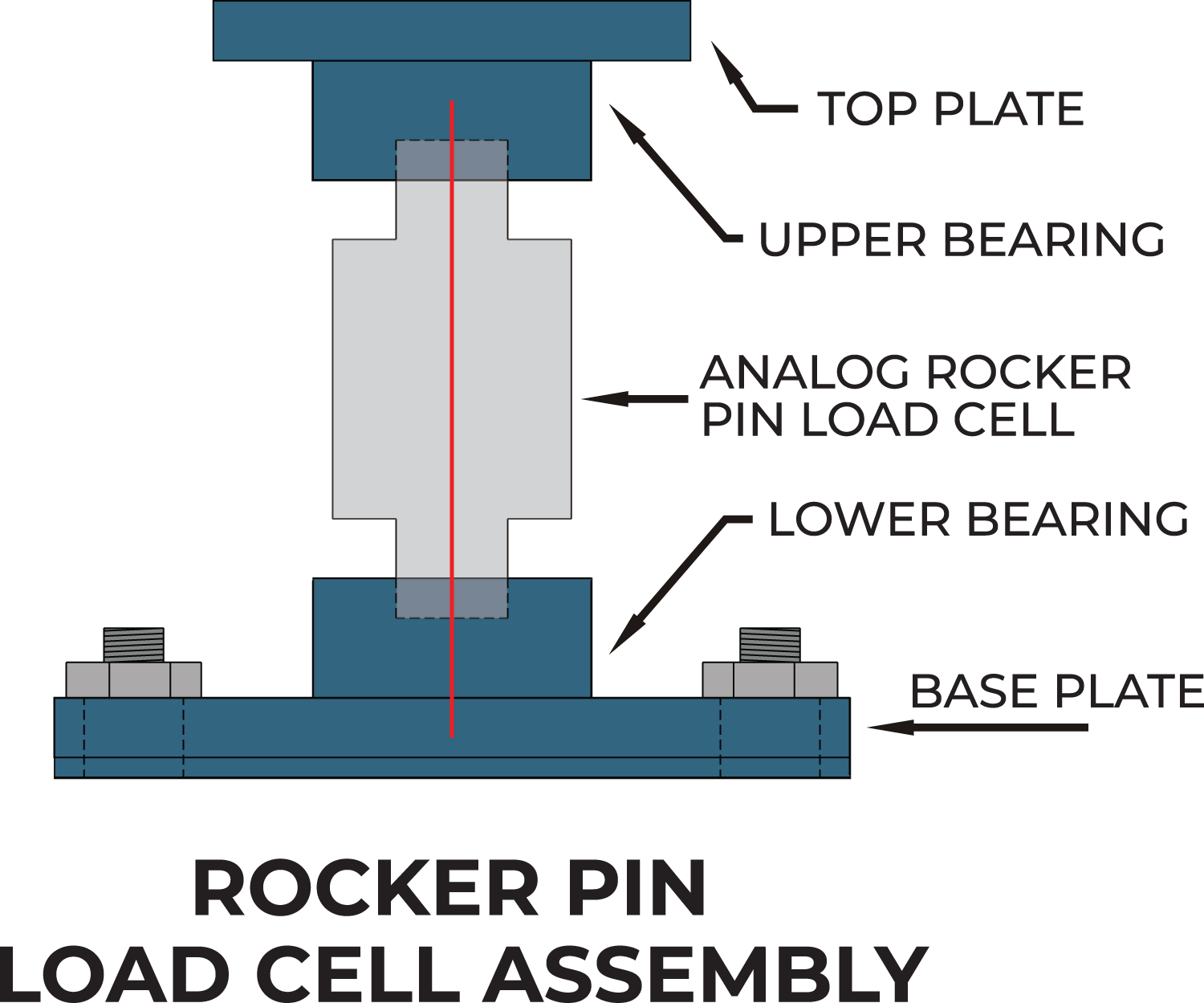

The rocker pin load cell allows a simple mounting arrangement with one lower and one upper bearing. The load cell is supplied with a rubber boot to protect the lower bearing from mud contamination. There are no links or pins to wear out. The mount allows for high-impact loading, typical of highway vehicles, and includes anti-rotation hardware. The rocker pin assembly compensates for thermal expansion of the weighbridge tolerating up to 5° off-center loading.

Polycarbonate NEMA 4-X corrosion proof summation boxes with captive gasket system are mounted on the side of the scale to protect against moisture and condensation entry into the load cell signal summing system and includes a patented waterproof vent system to prevent condensation forming in the summing boxes.

The Active Scale summing system is available with an optional remote section trimming kit located in the scale house allowing simple, fast initial and routine calibrations. The location of the remote calibration assembly in a controlled environment promotes the stability and accuracy of your scale and provides faster calibration.

Contact Us for All Your Weigh Scale Needs

even if we didn’t build or install your weigh scale.

Looking for a rental? We do that too!